Infrastructure

Infrastructure

Our company is spread over an area of 25000 sq. ft in Unit-1 and 40000 sq. ft in Unit-2.

We have the state-of-art infrastructure spread over a huge space, which enables us in

effectively performing our business operations. Constructed very deliberately, our units

support us in manufacturing wide range of industrial sheet metal pressed components

including the complex seat frame assembly components for automobiles.

Our facility is well equipped with different machines that facilitate us in stamping and

welding our products aptly. The machines that are required to manufacture the

varied products are well in place and are under stringent checks of our experts who keep

upgrading them from time to time. All the machines are efficiently operated by our

workforce to ensure flawless production

Our Machinery Details

- Pneumatic Press –25 Ton to 250 Ton Range

- Hydraulic Press – 40 Ton – 100 Ton

- NC Leveller Feeder – 3 Ton & 5 Ton

- CNC Tube Bending

- CNC Wire Bending

- CO2 MIG Welding Machine

- ROBO Co2 Welding

- Projection & Spot Welding

- Orbital Riveting Machine

- Tapping Machine

- Shearing Machine

Measuring Instruments :-

ROCKWELL HARDNESS TESTER

PROFILE PROJECTOR

VICKERS HARDNESS TESTER

MICROSCOPE

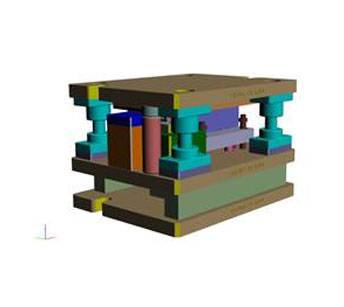

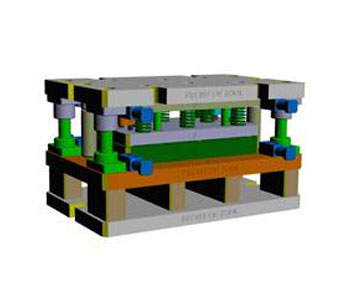

Own Design & Development :-

We have our own Design and Development facility for new Press Tools, Welding Fixtures and Checking Fixtures as per our customer drawings and requirements.